Hey, there’s something we’d like to share with you. Team Numnuts has been busy putting together some information about the invention of Numnuts and its development in Australia over the past two and a half years.

Sarah Birt collated the story of the device’s development, right down to the materials used, for the recent Sheepvention event in Hamilton, VIC. Meanwhile, founder Robin Smith has made a video outlining the R&D behind Numnuts. It’s aimed at a UK audience, but looks so good that we’re posting a shorter (5 minutes) version of it here.

So take your pick, or better still, enjoy them both as you take a well-earned break from lamb marking. We hope you find them interesting!

The Numnuts® Device was designed by the team at 4c Design Scotland, in close collaboration with Australian farmers. They wanted to offer the sheep industry a safe, precise, and efficient means to administer targeted and fast-acting pain relief directly to the site where a ring is placed for tail docking and castration.

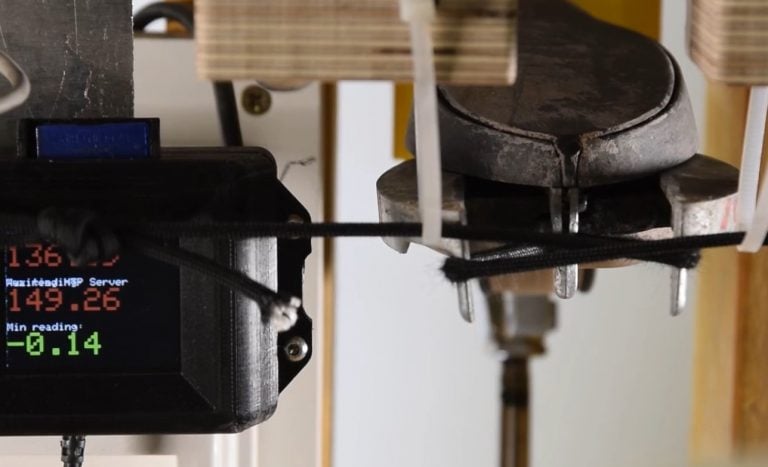

The design team met with Australian farmers and spent time in the paddock testing and designing a tool that Australian farmers would want to use. This collaboration had a significant influence on the final design of the device. Throughout the development and testing of the 17 major prototypes, and hundreds of smaller learning prototyes the design teams made sure to keep moving towards their goal.

While the original prototypes were made of various materials, including 3d printed plastic, and were a bit rough around the edges, our current commercial product has successfully merged the goals of 4c Design with the requirements of an average Australian sheep farmer to help improve ‘best practice’ for lamb marking.

For example, the plastic used in the Numnuts device is the same as that used to make the Milwaukee power drill, being robust but also affordable. Additionally, choosing a high-volume manufacturing process such as injection moulding once again means that the product is made to last without bumping up the costs.

Numnuts comprises three major sub-systems: ring applicator, injection system, and consumable Quick-Change Cartridges (QCCs) containing the branded local anaesthetic substance, NumOcaine®. The Numnuts system is entirely manual, requiring no external power source, and may be used equally effectively by left or right-handed operators with minimal on-farm training. It has been ergonomically developed from a user-centred perspective to offer ease of use and operator safety.

Using Numnuts is very easy, like the original Elastrator pliers. Just squeeze the handle to open the prongs and ring. Once the tail or testicles have been pulled through, release the handle. This will hold the targeted area in place ready for injection. With the free hand, press down the injection system on the top of the device to deliver the pre-calibrated dose of 1.5ml of pain relief directly into the spot required. To then detach the device from the ring, hold onto the tail or testicles and then roll the wrist back, raising the prongs upwards.

The Numnuts hardware is manufactured in Europe in a net-Zero manufacturing facility. When choosing the manufacturing techniques, engineering plastics, metals, and off-the-shelf components, the team was careful to make a selection that would stand up to the wear and tear of the farming environment, while remaining affordable as possible.

The final quality check happens here in Australia when the products are checked over, packaged, and sent on their way to warehouses or onto the next line of manufacturing. Our Quick Change Cartridges, after being quality checked, are sent to a family-owned animal health company in Brisbane, where they are fitted onto the NumOcaine bottles.

Register My Interest and Become Eligible to Distribute NumOcaine